8 Manufacturing Modes Approved for Microsoft Dynamics Business Central (BC)

pjoeckel • March 4, 2024

8 Manufacturing Modes Approved for Microsoft Dynamics Business Central (BC)

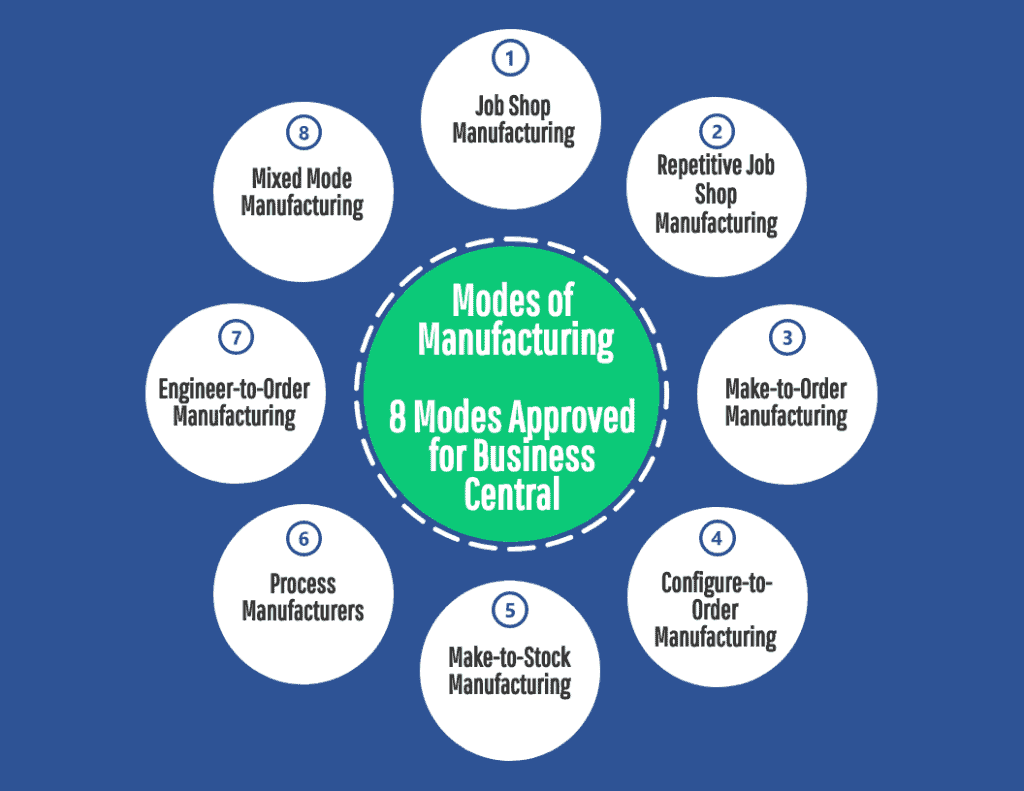

I have seen social media posts touting the eight modes of manufacturing that Microsoft Dynamics Business Central (BC) is approved for.

Here is the list:

BC is an excellent ERP (Enterprise Resource Planning) platform when implemented in the right company. However, my thirty years of selecting, implementing, and fixing ERP manufacturing software gave me pause about this claim. Let us examine that “8-Modes” claim with a real-life, data-driven example. I recently had the opportunity to consult with a company that builds large, extraordinarily complex machines engineered to order, combining a mix of standard equipment, unique components, and process manufacturing. Once completed, the business installs and services its machinery.

The business posed the following question, “We are implementing Microsoft Dynamics Business Central (BC), but some recently hired resources are questioning if that is the right solution for us.”

After asking a couple of detailed questions regarding their manufacturing requirements, I knew immediately that they were headed for severe challenges with their implementation. The challenge, of course, was how to quantify that analysis so that team members already invested in the BC implementation would have fact-based, data-driven analytics on which to base their decisions. To deliver that highly granular, non-biased, data-driven analysis, I turned to a GYDE365-Discover session.

In a matter of days, not weeks or months, I delivered a detailed analysis to the business comparing the fit of core BC functionality against the critical manufacturing requirements. In a detailed report of more than one hundred pages of thorough analysis, here was the key takeaway: Company-wide, for critical must-have requirements, BC was a fit for 52% of those requirements.

Of course, the devil is in the details, but drilling down into the missing requirements, it was easy to see that BC, with its current feature set, is a sub-optimal fit.

By contrast, the fit of Microsoft Dynamics Finance and Supply Chain Management (FSCM) was evaluated at 89%. Suppose you need a fact-based, unbiased analysis of your manufacturing operations requirements compared to BC, FSCM, and any other ERP solution. In that case, a GYDE365-Discover report is the best methodology I have seen. Let us show you how and why with data, not opinions .

Here is the list:

- Job Shop Manufacturing

- Repetitive Job Shop Manufacturing

- Make-to-Order Manufacturing

- Configure-to-Order Manufacturing

- Make-to-Stock Manufacturing

- Process Manufacturing

- Engineer-to-Order Manufacturing

- Mixed Mode Manufacturing

BC is an excellent ERP (Enterprise Resource Planning) platform when implemented in the right company. However, my thirty years of selecting, implementing, and fixing ERP manufacturing software gave me pause about this claim. Let us examine that “8-Modes” claim with a real-life, data-driven example. I recently had the opportunity to consult with a company that builds large, extraordinarily complex machines engineered to order, combining a mix of standard equipment, unique components, and process manufacturing. Once completed, the business installs and services its machinery.

The business posed the following question, “We are implementing Microsoft Dynamics Business Central (BC), but some recently hired resources are questioning if that is the right solution for us.”

After asking a couple of detailed questions regarding their manufacturing requirements, I knew immediately that they were headed for severe challenges with their implementation. The challenge, of course, was how to quantify that analysis so that team members already invested in the BC implementation would have fact-based, data-driven analytics on which to base their decisions. To deliver that highly granular, non-biased, data-driven analysis, I turned to a GYDE365-Discover session.

In a matter of days, not weeks or months, I delivered a detailed analysis to the business comparing the fit of core BC functionality against the critical manufacturing requirements. In a detailed report of more than one hundred pages of thorough analysis, here was the key takeaway: Company-wide, for critical must-have requirements, BC was a fit for 52% of those requirements.

Of course, the devil is in the details, but drilling down into the missing requirements, it was easy to see that BC, with its current feature set, is a sub-optimal fit.

By contrast, the fit of Microsoft Dynamics Finance and Supply Chain Management (FSCM) was evaluated at 89%. Suppose you need a fact-based, unbiased analysis of your manufacturing operations requirements compared to BC, FSCM, and any other ERP solution. In that case, a GYDE365-Discover report is the best methodology I have seen. Let us show you how and why with data, not opinions .

With a GYDE365-Discover assessment, you'll receive an in-depth analysis report pack that includes:

- Recommended modules based on your company's processes

- Defined list and analysis of your company's requirements

- Gap/fit analysis to Dynamics Business Central and FSCM (easily benchmark to non-Microsoft ERP solutions if desired)

- Implementation project estimates, including timeline, budget, and licensing costs

- RFP/RFI-ready documents

- ...and much more!

The graphic below is for reference only. It is part of the LinkedIn post referenced in the blog.

HandsFree ERP is dedicated to supporting clients with their ERP initiatives, enabling companies to seamlessly connect users with their ERP partners. By utilizing skilled professionals, streamlined processes, and cutting-edge tools, HandsFree ERP significantly boosts the success rates of ERP projects.

By pjoeckel

•

July 2, 2024

Understand the critical role of data quality in the successful implementation of Dynamics Copilot in ERP systems. Learn how robust data governance can enhance the accuracy and reliability of GenAI outputs, ensuring your business reaps the full benefits of advanced AI technologies.